Introduction

There are several printing methods that are used in making hoodies. Five of these methods are:

-

Screen Printing

-

Direct to Garment

-

Heat Transfer

-

Sublimation

-

Embroidery

Each of these methods is described in the following sections.

Screen Printing

Screen printing has been around a long time. It first appeared in China in the Song Dynasty (960-1279 AD).1 The first step in the process is to create the artwork to be printed. Assuming the artwork has only one color, a stenciled design is created from the artwork. In commercial printing, the stenciled design is created on a fine mesh screen. There are several methods for creating the stencil. The garment to be printed is then placed on a smooth surface. The mesh screen is placed over the garment. Ink is then put on the mesh screen, and a squeegee is moved back and forth over the mesh. The ink transfers to the garment placing the desired image on the garment. The ink is then dried to set the image.

If there are multiple colors in the design, a stencil must be created for each color. The entire printing process is then repeated for each color. A digital scanner, connected to a computer, is used to scan the artwork and separate each color so that a separate stencil can be created for each color. An excellent video at Screen Printing: How It Works shows entire process from scanning the image to printing the garment.

Screen printing can create vibrate colored garments, however, there are significant setup costs because multiple stencils must be created. Generally, machines with multiple print heads will be employed. This type of printing would be suited for producing a large quantity of garments where the setup costs can be spread over all the garments produced.

Direct-to-Garment

DTG printing does not require a stencil as screen printing does. Therefore, it is suitable for printing small quantities of a design on garments. DTG printing is also precise, allowing detailed designs to be printed. DTG images can be slightly more faded than screen printed images.

Heat Transfer

Heat Transfer is a newer printing method. The desired image is first printed on a transfer paper. The ink on the paper is then transferred to the garment using heat and pressure. Standard ink-jet printers, such as the Epson printer shown on the right, can be used to print the image on the transfer paper.

After the image is printed on the transfer paper, the transfer paper is inserted into a heat press along with the garment that will get the image. The transfer paper is then pressed on the garment, and heat and pressure are applied. The ink on the transfer paper melts off the paper and transfers to the garment. 2

Sublimation

Sublimation is the transition of a substance directly from the solid to the gas phase, without passing through the intermediate liquid phase. A good example of sublimation is dry ice. Dry ice is solid, frozen carbon dioxide which turns directly into a gas at -109.3°F.

Embroidery

If You Want Some Help

If you’ve decided you want to go ahead with creating a custom hoodie, but you want some assistance, our firm, LowSport, is here to help. LowSport has been in the fan wear business for over 30 years. We specialize in custom made fan wear and corporate fashion. LowSport specializes in high end products that utilize made to order production in their oversees factories. LowSport has very special factory relationships that allow for very fast turn around of less than 30 days and even quicker in many cases. Our minimum orders are virtually non existent. You can contact us at our phone number: +1.914.572.1584 or email us at: glow@lowsportllc.com.

Sources

- Roberts, Gordon, “History’s Influence on Screen Printing’s Future”, SCREENPRINTING, May 4, 2006, https://screenprintingmag.com/historys-influence-on-screen-printings-future/

- Stone, Dan, “What Is Heat-Transfer Printing?”, Techwalla, https://www.techwalla.com/articles/what-is-solvent-ink

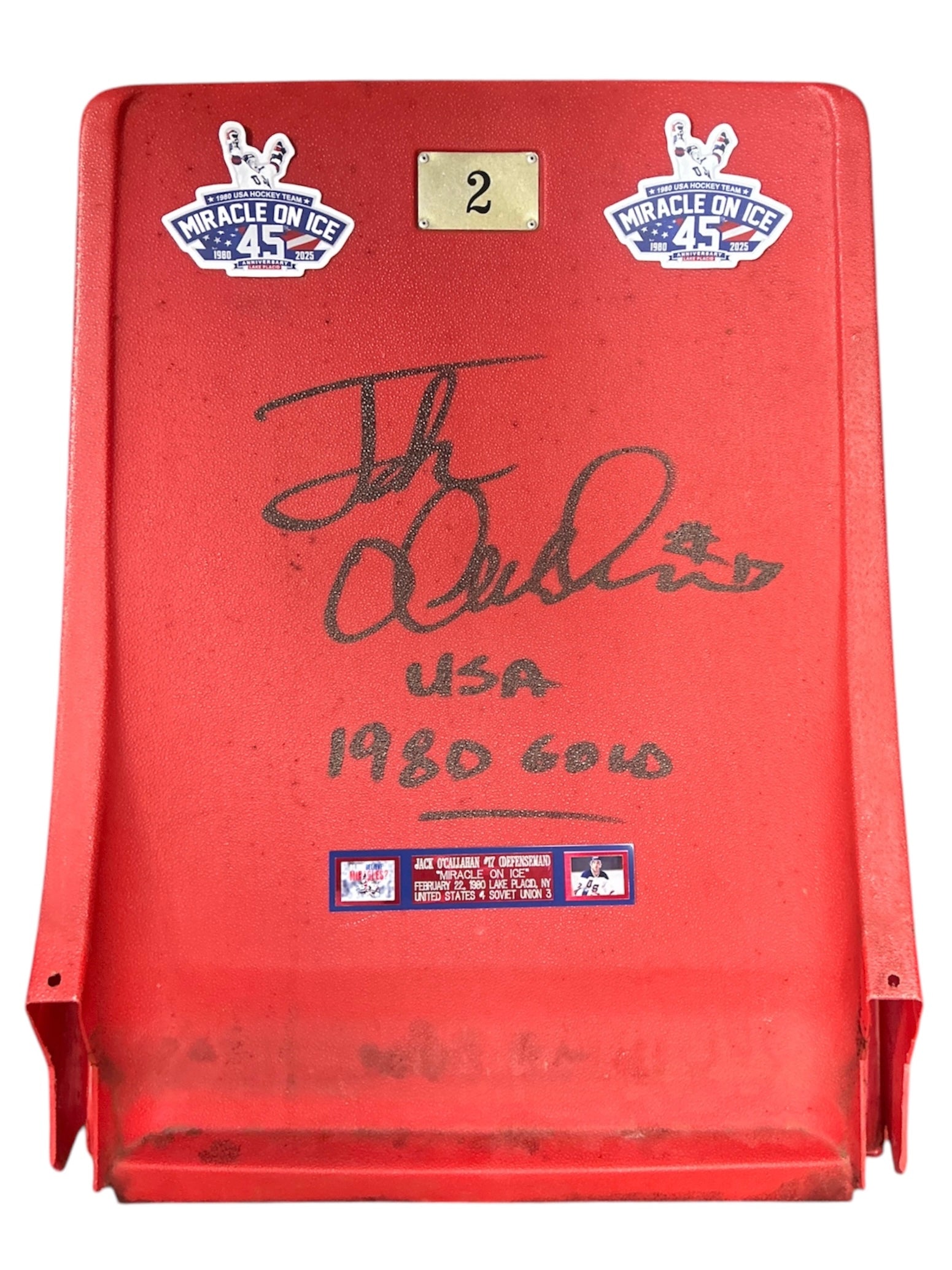

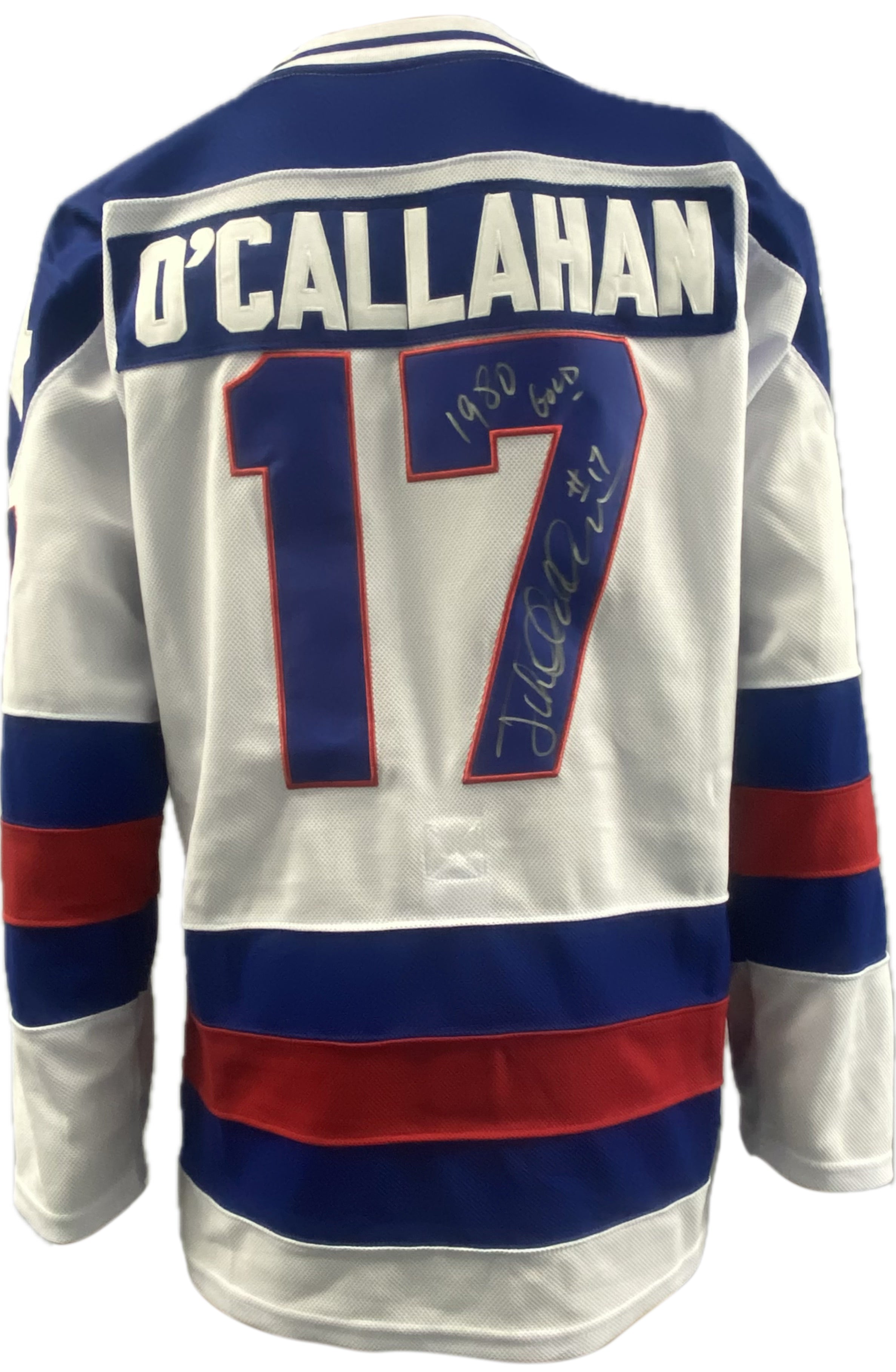

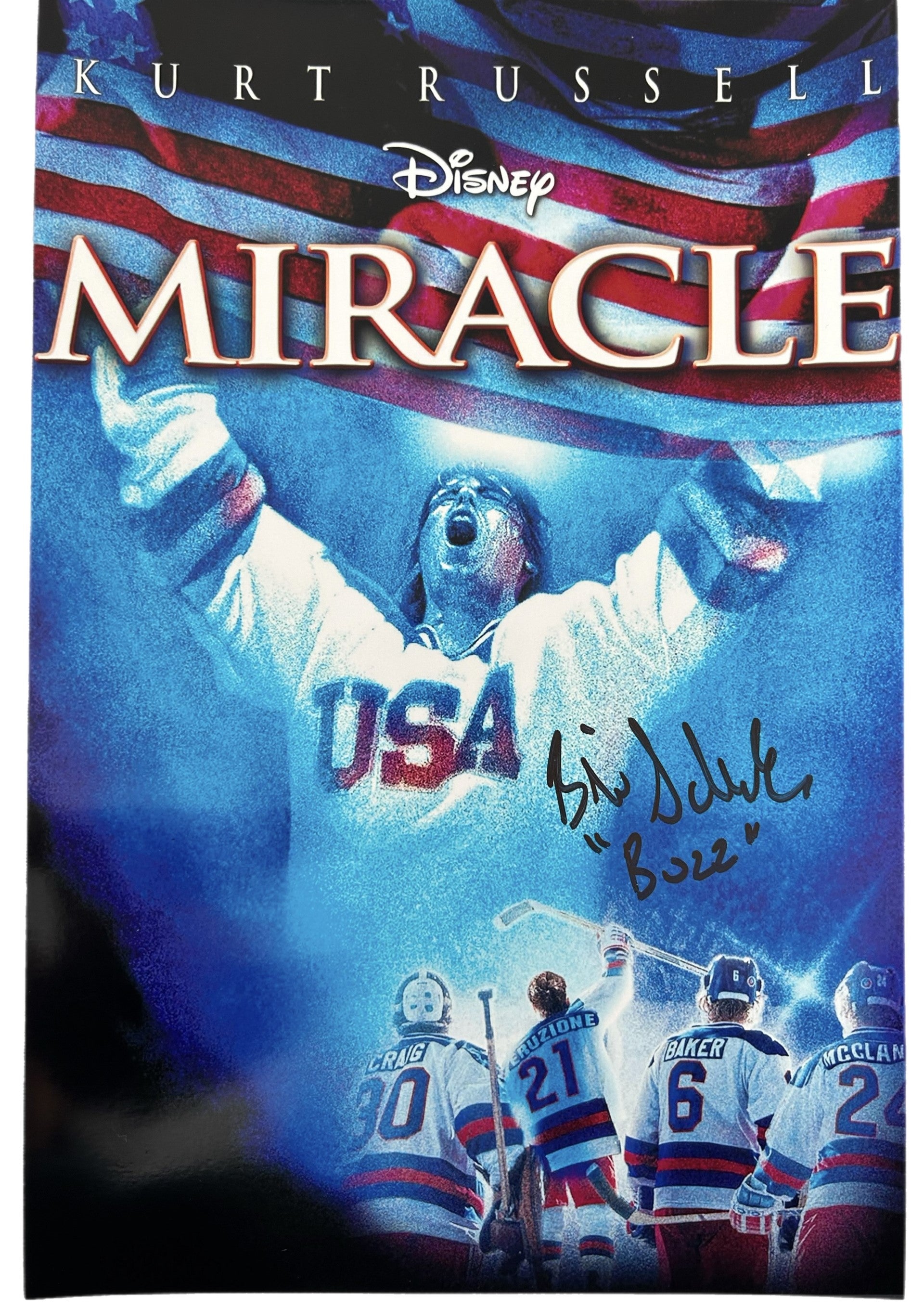

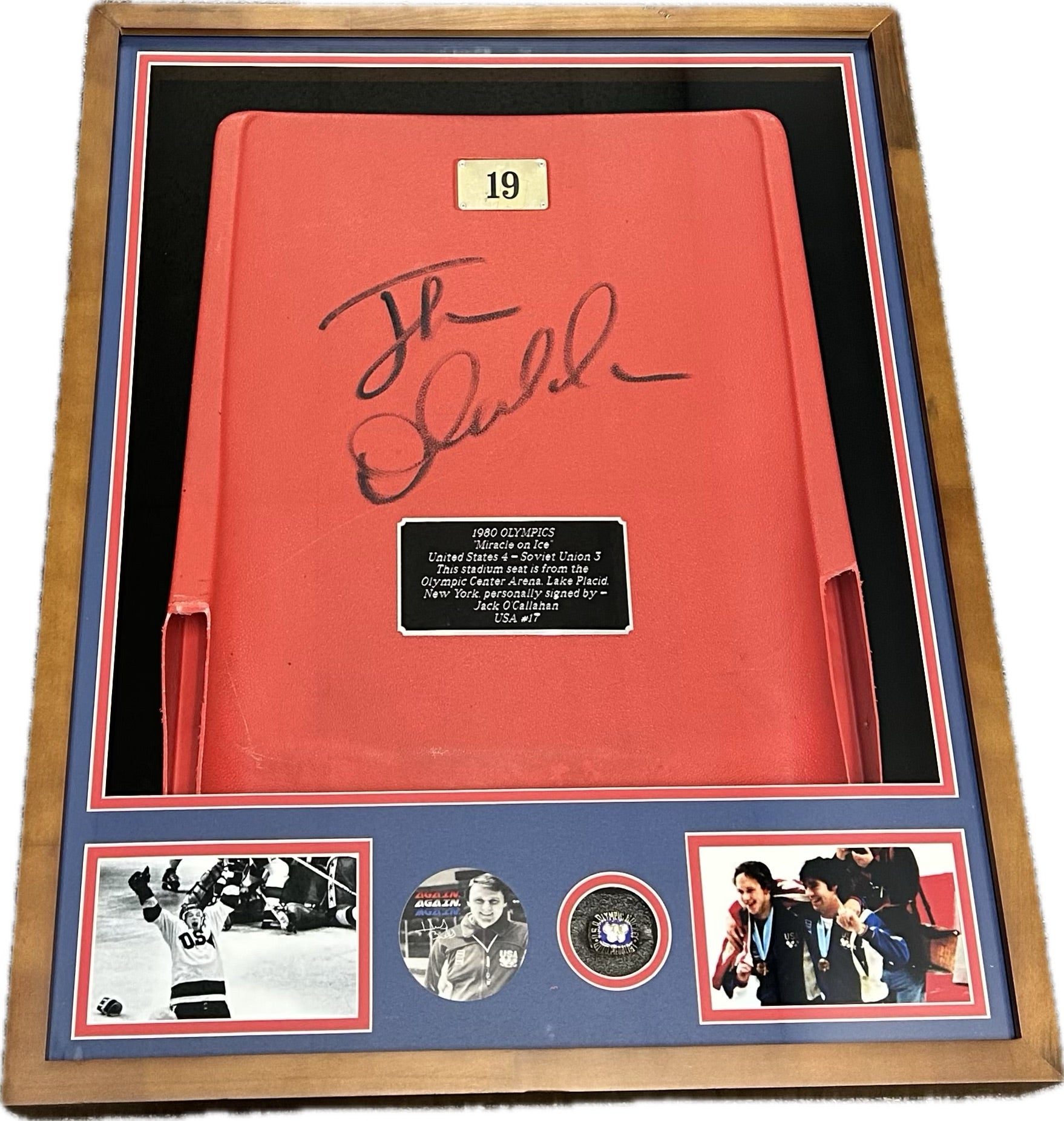

Miracle on Ice

Miracle on Ice

Team USA Hockey

Team USA Hockey

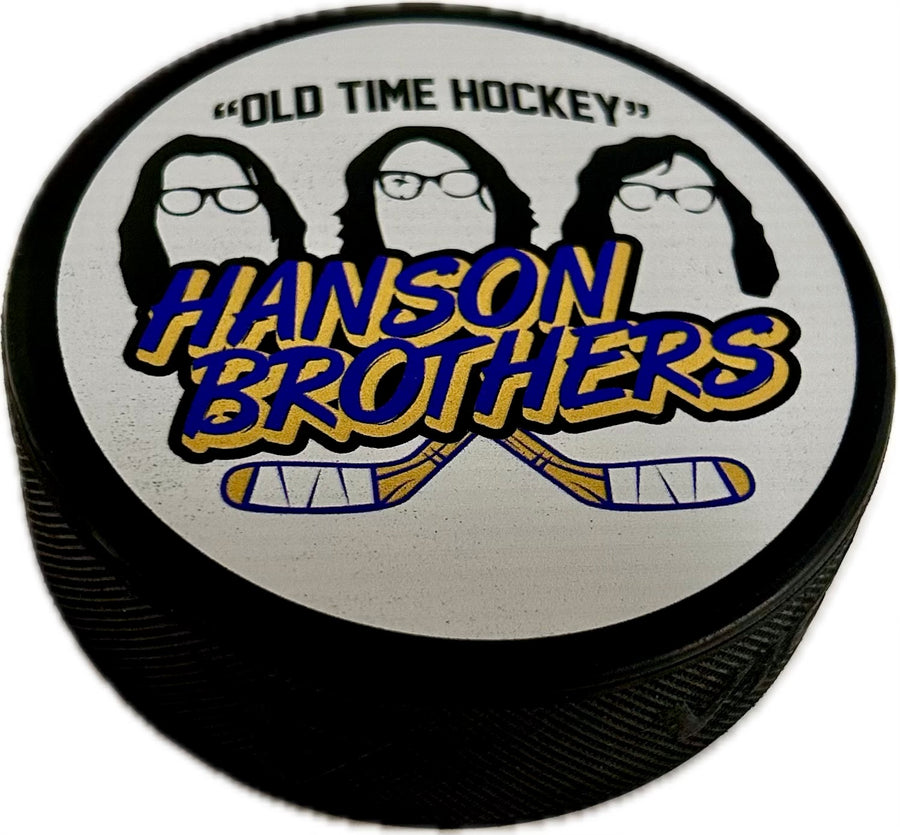

Hockey Teams and Winter Sports Collection

Hockey Teams and Winter Sports Collection

Shelby Cobra & Other Motorsports

Shelby Cobra & Other Motorsports