Introduction

Determining the cost of a custom hoodie involves many factors. First and foremost is the cost of the fabric. Other considerations are manufacturing cost, order quantity, design cost, packing, shipping and operating expenses. Let’s take a deeper look at each of these.

Fabric Cost

Although there are many factors that determine the cost of a hoodie, no factor is more important that the fabric cost. The cost of the fabric alone can be 60% to 70% of the cost of a custom hoodie. The three most popular fabrics for hoodies are cotton, polyester, and cotton/ polyester blends. Cotton is the most expensive and polyester is the least expensive. The cost of cotton/ polyester blends fall somewhere in between. Approximately 2-3 yards of fabric are needed to construct the hoodie. Representative costs for the fabrics are as follows. A 100% cotton fabric is sold for between $12.62 and $14.95 per yard. A polyester/ cotton blend for hoodies is sold for between $6.28 and $10.23 per yard. A 100% polyester hoodie fabric can be found for around $4.00 per yard.

Manufacturing Cost

The second highest cost in constructing a hoodie is the manufacturing cost. Where the hoodie is manufactured has a big impact on this cost. The article ‘Manufacturing labor costs per hour for China, Vietnam, Mexico from 2016 to 2020‘ contrasts the manufacturing costs in these three countries. 1 As stated in the article – “In 2018, manufacturing labor costs in China were estimated to be 5.51 U.S. dollars per hour. This is compared to an estimated 4.45 U.S. dollars per hour in Mexico, and 2.73 U.S. dollars in Vietnam.” The construction of a hoodie takes 1 to 2 hours. So the cost in the three countries would range from: $5.51 to $11.02 in China; $4.45 to $8.90 in Mexico, and; $2.73 to $5.46 in Vietnam. Typically, labor cost percentages average 20 to 35 percent of gross sales. 2 The manufacturing cost is also impacted by the complexity of the hoodie design. If the design involves appliqué or embroideries the cost will increase accordingly.

Design Cost

If the customization of the hoodie only involves putting text and a logo on the hoodie, the design cost is minimal. But if you desire a high end product, such as an appliqué hoodie with multiple embroideries, much more is involved. Such high end products must be designed. Graphic designers will be required to turn your logos and desired text into great designs. The average cost of a graphic designer is $65-$70 per hour. 3 Assuming 1-2 hours is required to design the hoodie, the design cost would range between $65-$140. This cost would be spread across all hoodies ordered. So if 100 hoodies were ordered, the cost per hoodie would range between $0.65-$1.40. If you are ordered higher quantities of hoodies, this seems like money well spent.

Order Quantity

Discounts are typically given for ordering in larger quantities. An example of a discount policy is shown at the right. As can be seen, a substantial discount of 30% is given for ordering in larger quantities. Since the fabric cost is the most significant cost in constructing a hoodie, it stands to reason that it would be beneficial to produce several hoodies of a given design to reduce costs.

Fulfillment Cost

After a hoodie is manufactured, it must be packaged and shipped, obviously adding to the cost of the hoodie. Fulfillment costs involved for a custom hoodie include a setup fee, storage fees for warehouse storage, packaging and shipping fees. The higher the quantity of hoodies packaged and shipped the lower the cost per hoodie. Shipment costs are determined by the location of the manufactured hoodie, and the final shipping location. It is difficult to estimate these costs because there are too many factors involved. Companies that provide fulfillment services generally provide little guidelines for fulfillment costs. Instead, they ask for the details on the fulfillment requirements, and then they will provide a quote. Ballpark costs for shipping from China are found in the reference cited below – “For general goods weight starts from 0.5 kg to 10 kg, the shipping fee is around $20 to $100, from general goods weight from 10kg to 20kg the shipping fee is around $100 to $200, for goods weight from 21 kg to 100 kg the shipping fee is around $200 to $500.”4

Operating Expenses

Operating expenses are those costs which businesses incur to keep the doors open. These are expenses not directly to the production of a product. They include rent, utilities, payroll, taxes, equipment rental, insurance, office supplies, legal fees and marketing. Much like fulfillment costs, operating expenses depend a great deal on the location of the company. In general, for example, operating expenses are much less in Mexico than the United States. The normal operating expense is typically between 60% to 80% of gross income. 5

Putting It All Together

Googling “custom hoodie” yields some startling low prices for a custom hoodie. But be careful. An advertised price of $9.30, for example, is for an order of 5000 hoodies, and it does not include cost of printing and shipping. And this is for a simple custom hoodie that just includes some text and a logo. More realistically, combining the minimum costs cited above, we find the following costs for 1 custom hoodie: fabric cost for 2 yards of polyester – $8.00; construction cost for 1 hour of labor in Vietnam – $2.73. This yields a cost for 1 custom hoodie to be $10.73 not including design costs, packing, shipping and operating expenses. By way of comparison, a plain hoodie my be purchased on Amazon for $10.99 plus tax and shipping. A hoodie with some plain text may be purchased for $25.90 plus shipping. If you desire a hoodie like the one pictured above, some design costs will be involved. Spread across a quantity such as 100 hoodies, the design costs are small, and seem well worth it.

If You’re Looking for Help

If you’ve decided you want to go ahead with creating a custom hoodie, but you want some assistance, our firm, LowSport, is here to help. LowSport has been in the fan wear business for over 30 years. We specialize in custom made fan wear and corporate fashion. LowSport specializes in high end products that utilize made to order production in oversees factories. LowSport has very special factory relationships that allow for very fast turn around of less than 30 days and even quicker in many cases. Our minimum orders are virtually non existent. You can contact us at our phone number: +1.914.572.1584 or email us at: glow@lowsportllc.com.

Sources

- Duffin, Erin, “Manufacturing labor costs per hour: China, Vietnam, Mexico 2016-2020”, statista, Aug 9, 2019, https://www.statista.com/statistics/744071/manufacturing-labor-costs-per-hour-china-vietnam-mexico/

- Adkins, William, “How to Calculate the Employee Labor Percentage”, Chron, January 31, 2019, https://smallbusiness.chron.com/calculate-employee-labor-percentage-15980.html

- “How Much Does a Graphic Designer Cost?”, cost helper small business, https://smallbusiness.costhelper.com/graphic-designer.html

- Hilon, Carol, “What’s the average Alibaba.com shipping price from China to the U.S?”, Quora, August 17, 2016, https://www.quora.com/Whats-the-average-Alibaba-com-shipping-price-from-China-to-the-U-S

- “Operating Expense Ratio”, AgDirect, 12/15/2015, https://www.agdirect.com/resources/learning-center/operating-expense-ratio?AspxAutoDetectCookieSupport=1

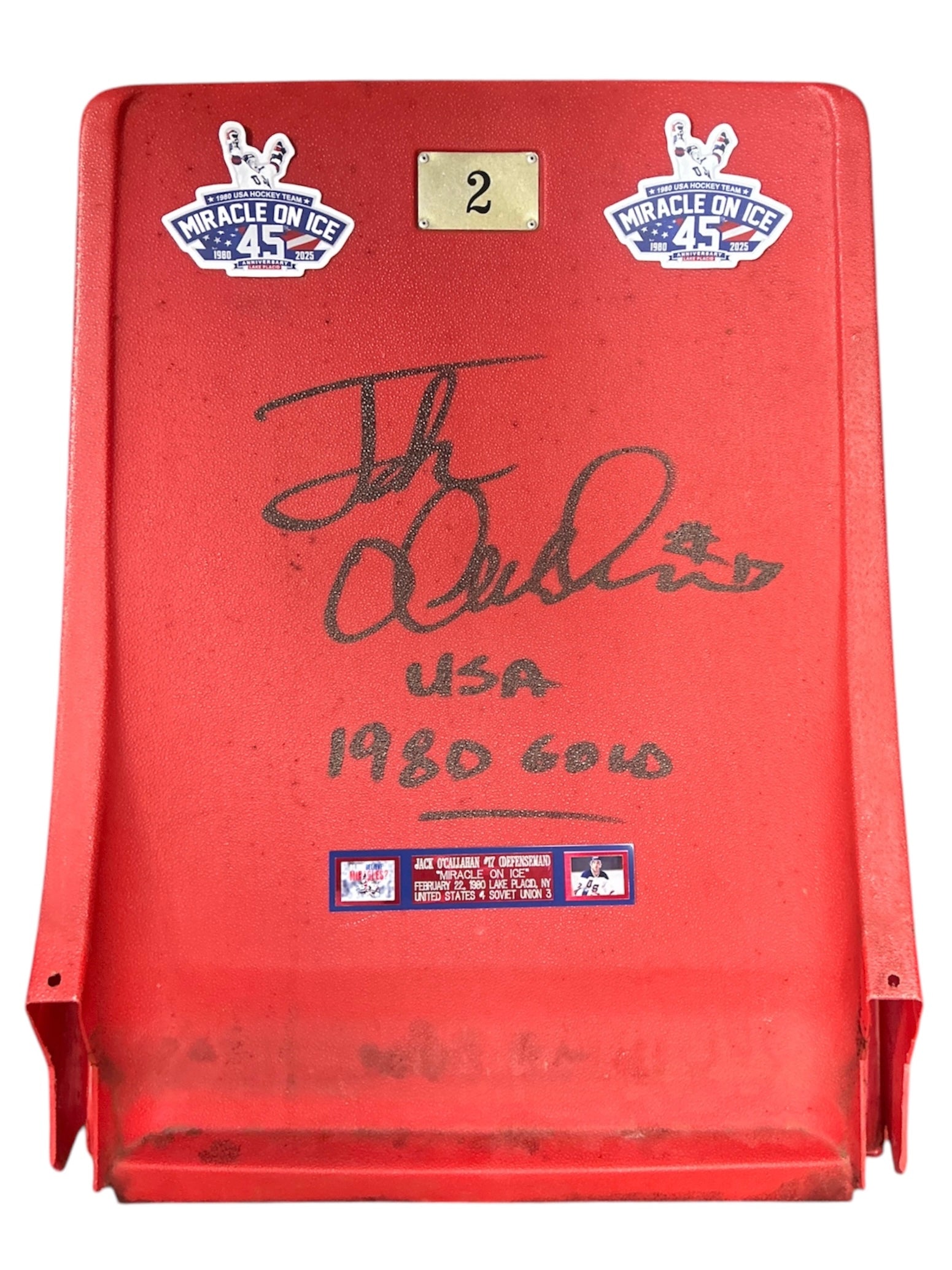

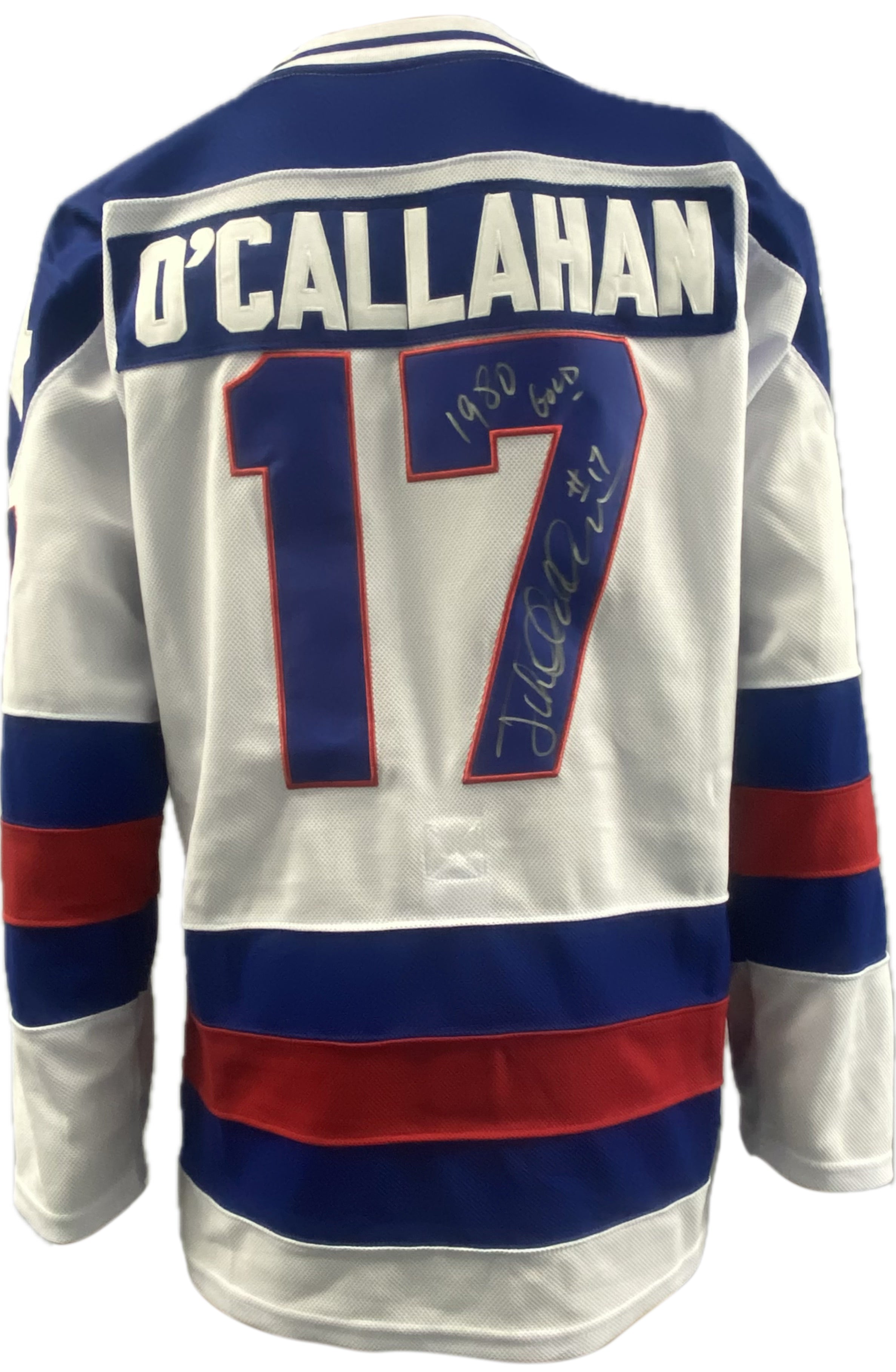

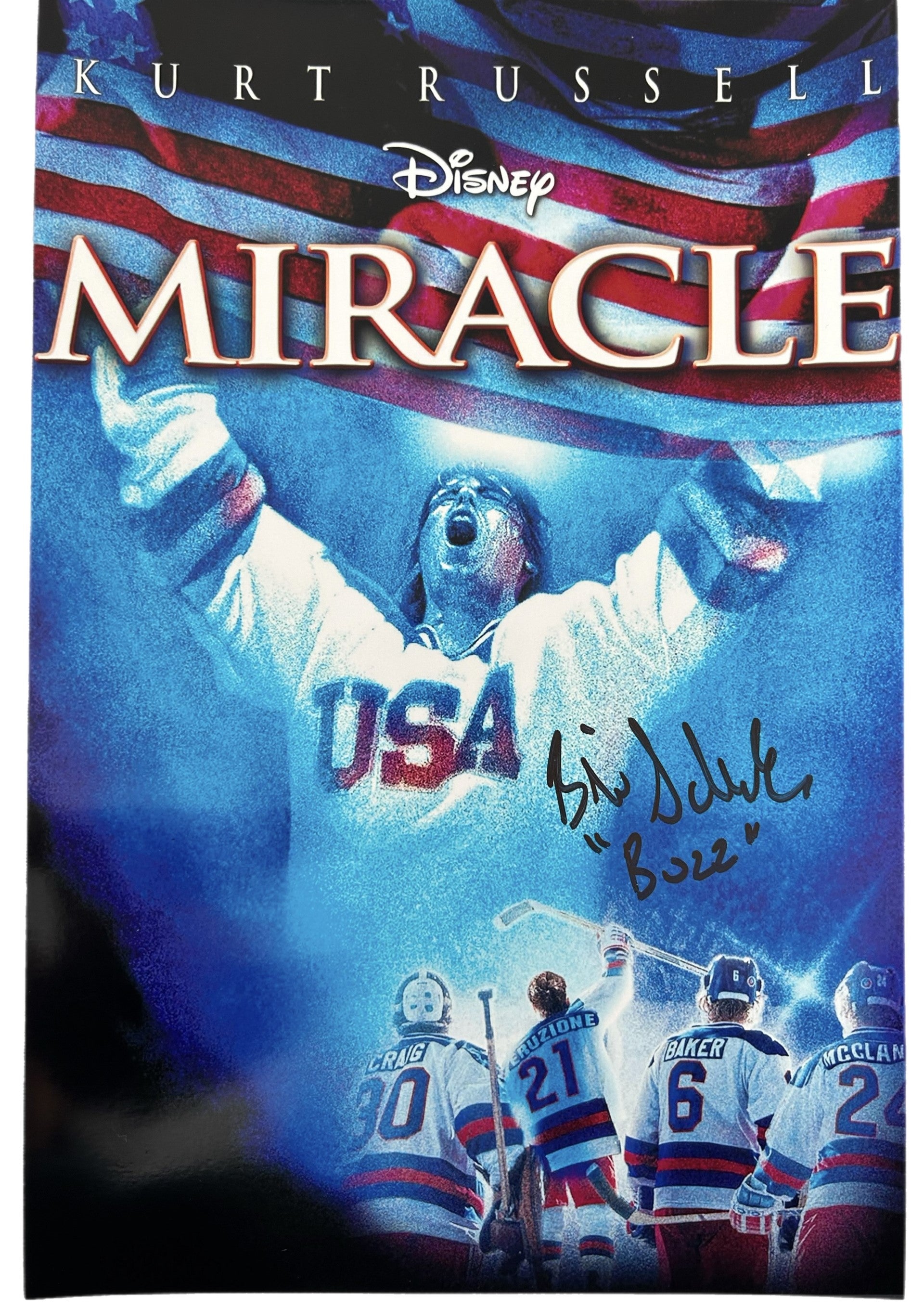

Miracle on Ice

Miracle on Ice

Team USA Hockey

Team USA Hockey

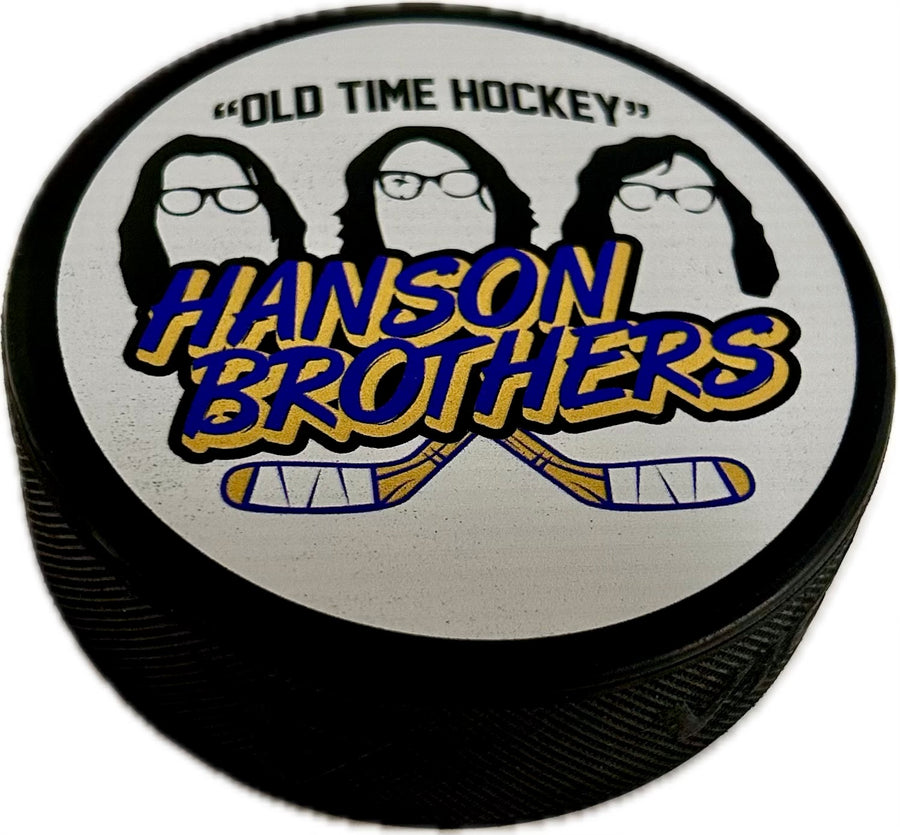

Hockey Teams and Winter Sports Collection

Hockey Teams and Winter Sports Collection

Shelby Cobra & Other Motorsports

Shelby Cobra & Other Motorsports